Machines that perform exactly as expected!

Home / Products / Head and tailstock positioners / Head and tailstock two-axis positioners

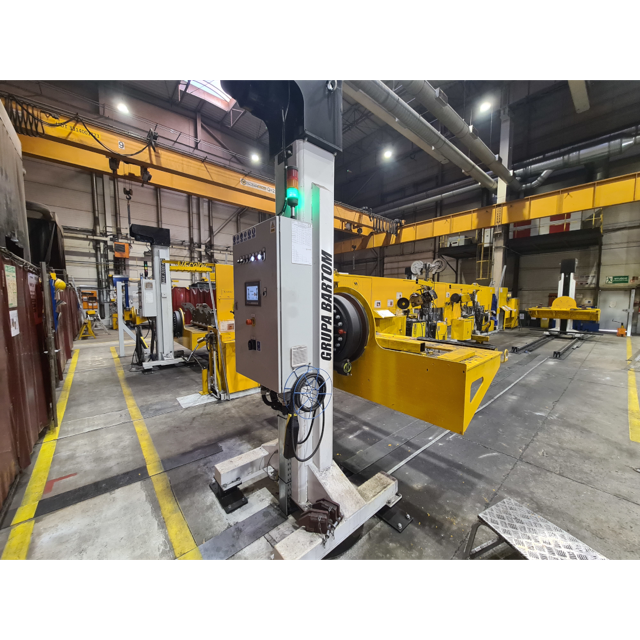

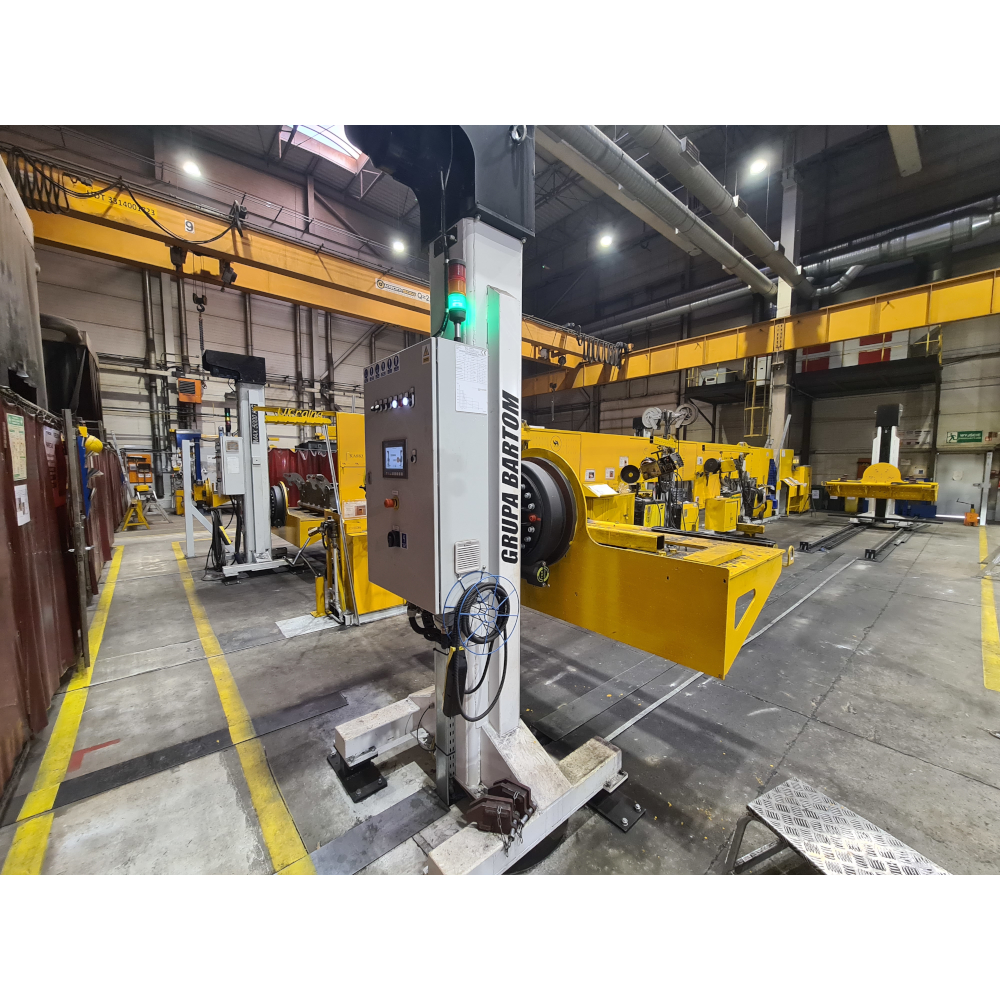

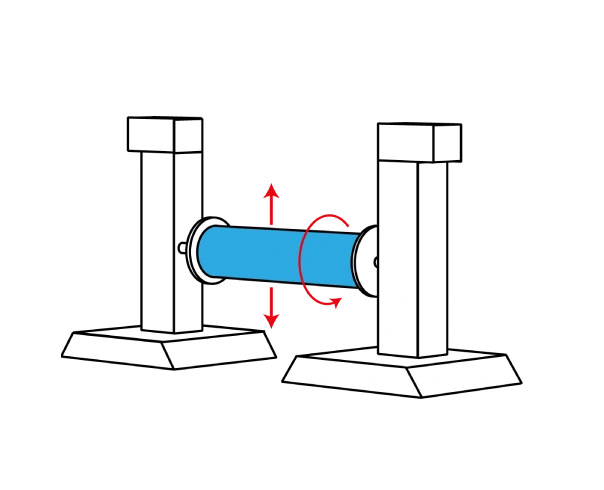

Head and tailstock two-axis positioners

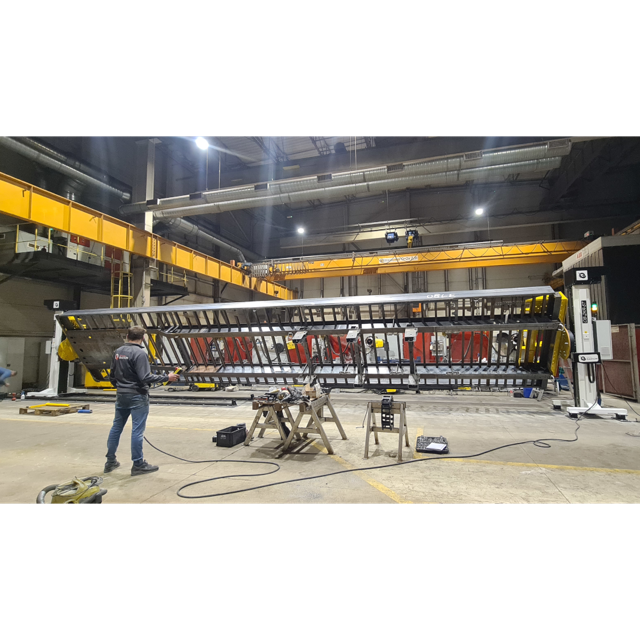

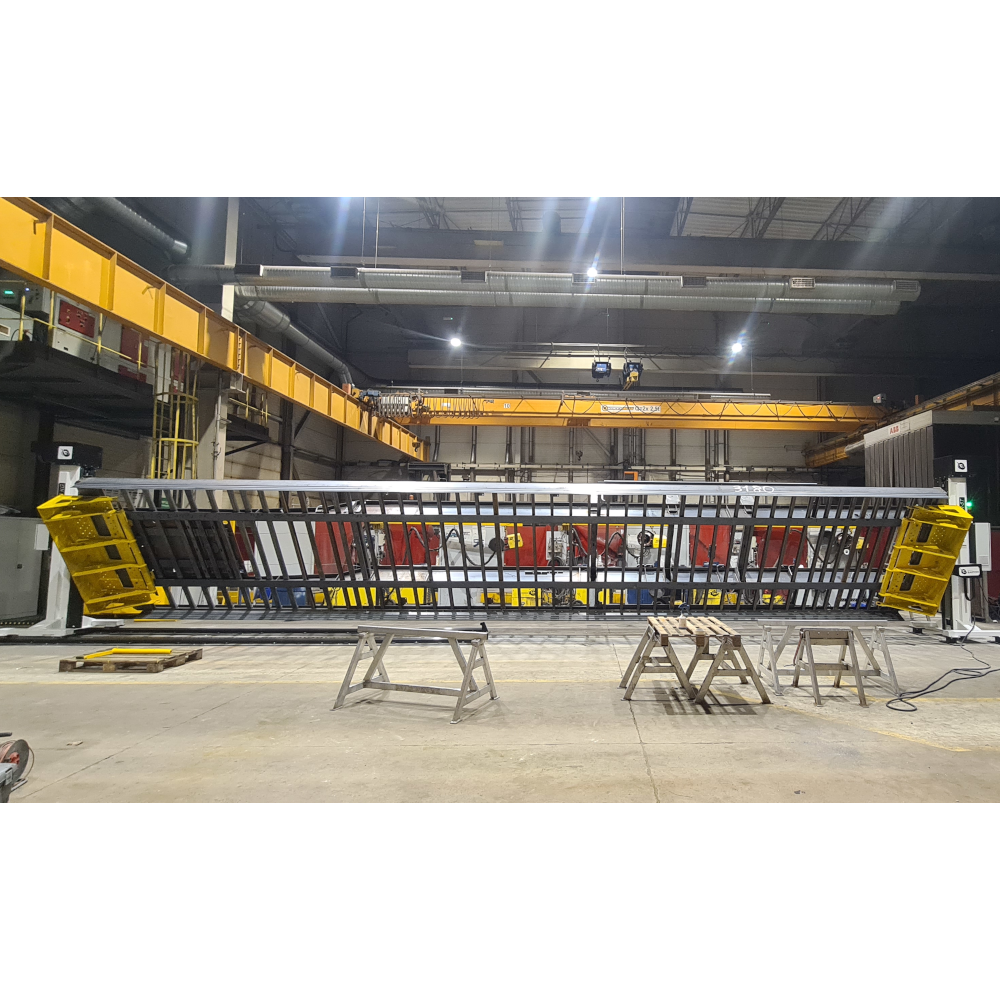

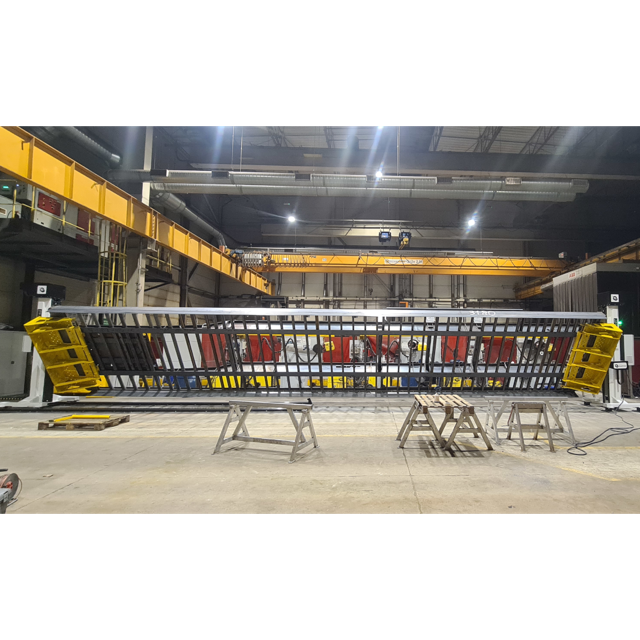

OB-2KR series head- and tailstock two-axis positioners allow positioning of workpieces in two axes, making them indispensable for welding long and wide components. They are most commonly used for welding tanks, silos, pressure vessels, and trailer frames.

The use of positioners significantly improves workplace safety, reduces processing time by up to 70%, and ensures top-quality welds.

Optional features:

mobile head- and tailstock

rail system

rotation drive on both columns

nut wear sensors

laser rangefinders

automatic reels for communication cables

Precise rail system – simplifies the assembly of repeatable components, without the need for precise column alignment.

Mobile carriage for tailstock – enables easy relocation of the tailstock without the need for rail installation.

| Model | Workpiece weight (kg) |

Max diameter of workpiece (mm) |

Axis lifting mechanism |

Rotation speed (RPM) |

Height adjustment range (mm) |

Voltage (V) |

|---|---|---|---|---|---|---|

| OB-2KR-1T | 1000 | 3000 | screw | 0.12-1.2 | 500-1600 | 3x400 |

|

||||||

| OB-2KR-3T | 3000 | 3000 | screw | 0.12-1.2 | 600-1600 | 3x400 |

|

||||||

| OB-2KR-5T | 5000 | 3400 | screw | 0.11-1.1 | 700-1800 | 3x400 |

|

||||||

| OB-2KR-8T | 8000 | 3850 | screw | 0.1-1 | 700-2000 | 3x400 |

|

|

||||||

| OB-2KR-12T | 12000 | 3850 | screw | 0.06-0.6 | 700-2300 | 3x400 |

|

|

||||||

Optional programmable control system.

THREE-NUT SYSTEM: LOAD, CONTROL, AND SAFETY NUT

HIGH-QUALITY SELF-LOCKING TRAPEZOIDAL SCREW

TRIPLE SAFETY SYSTEM

ENCODER BASED MOVEMENT SYNCHRONIZATION VIA PROFINET

HMI PANEL WITH MULTILINGUAL SUPPORT

Tailstock guides – enable easy positioning without any elements protruding above floor level.

We offer custom-built machines tailored to individual requirements, as well as design support and the production of fixtures adapted to specific workpieces. These solutions significantly reduce the time needed to position components on the positioner.

Solutions tailored to your needs

Our Design Department combines years of expertise with innovative thinking to deliver fully customized solutions. We design machines that go beyond standard models, precisely tailored to your specific requirements.

Flexible solutions

Flexible solutions Individual approach

Individual approach Focus on safety

Focus on safety Easy expansion

Easy expansion