Machines that perform exactly as expected!

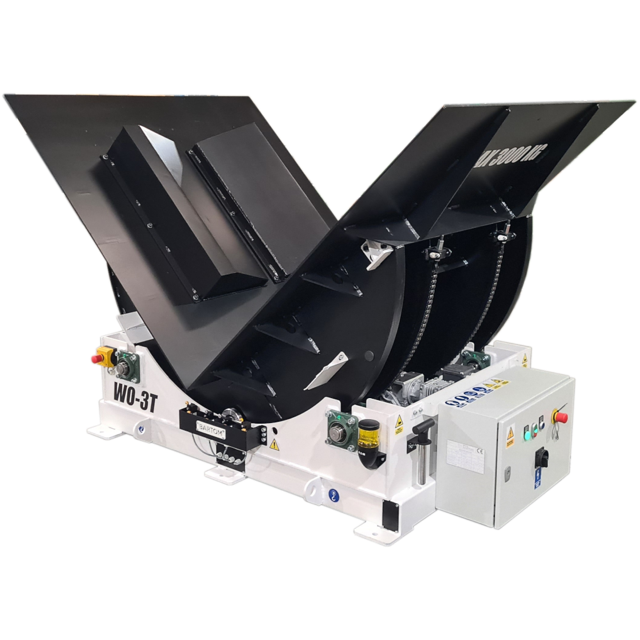

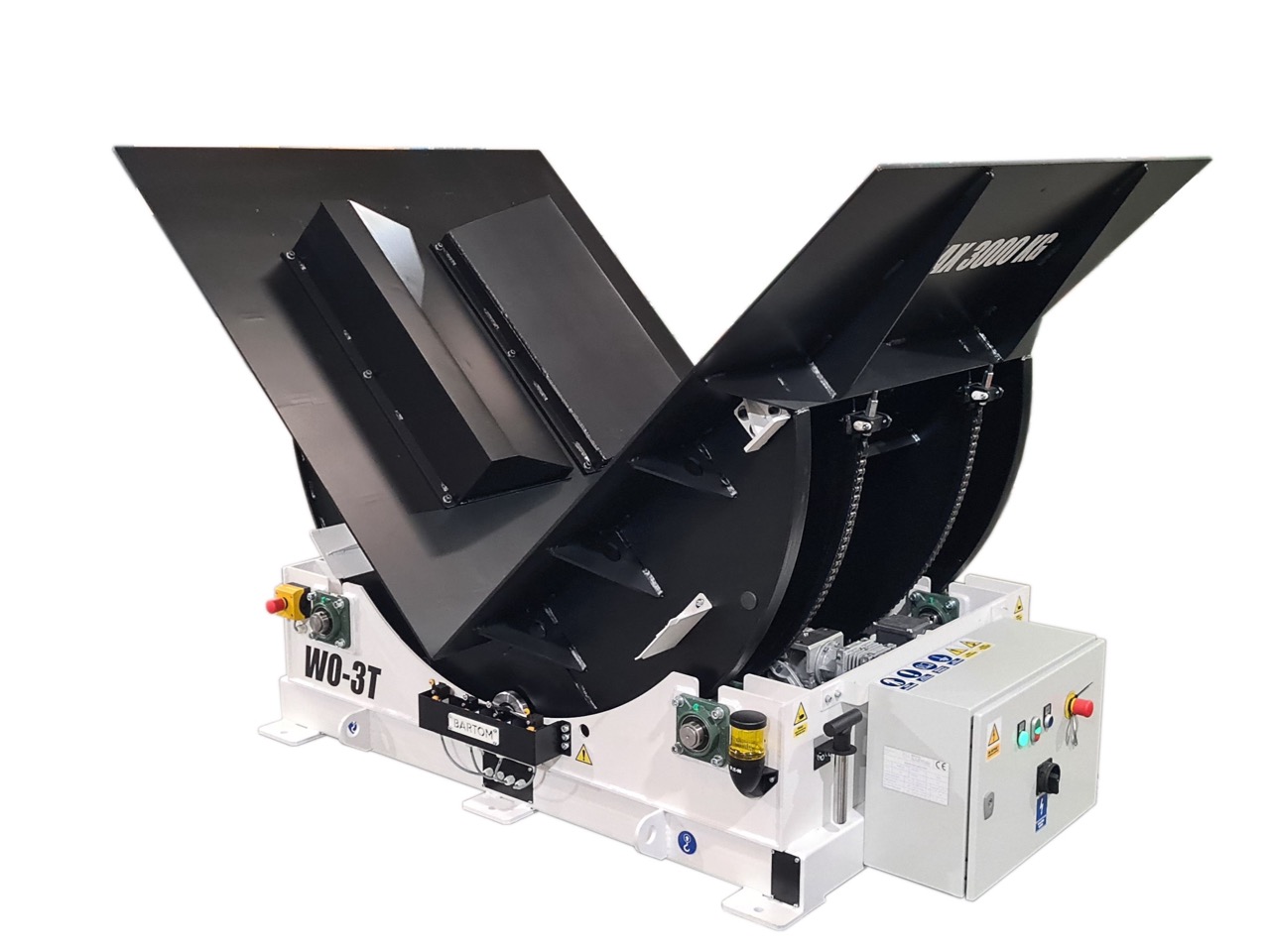

Upenders / Die and mould rotators

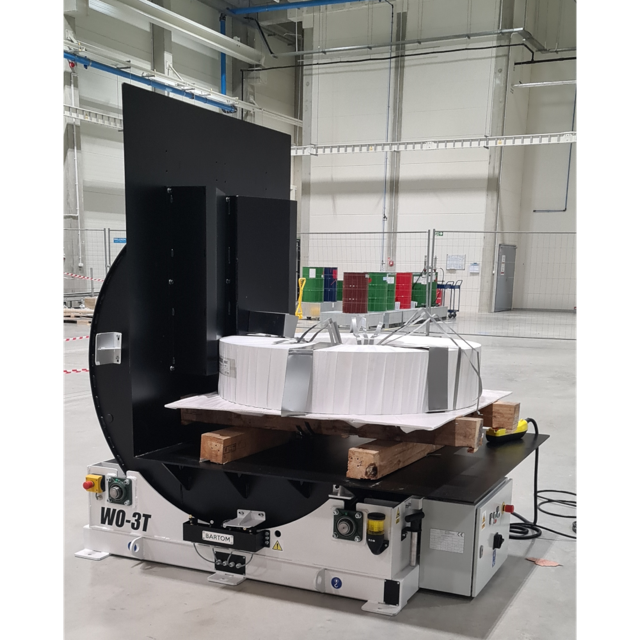

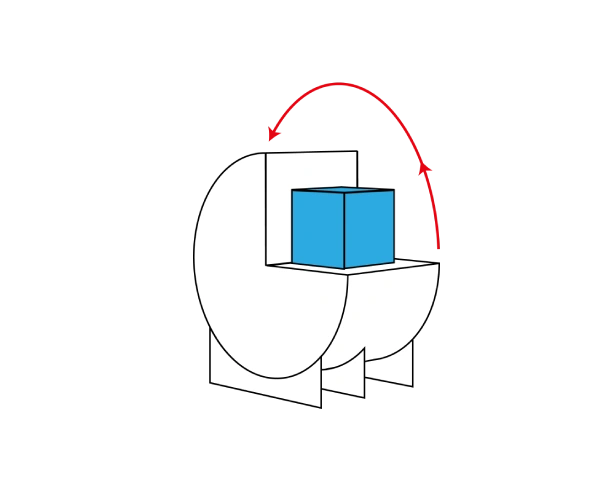

WO Upenders enable easy 90-degree rotation of large workpieces. This enhances operator safety and prevents damage to the workpiece.

Upenders are the ideal solution when metal coils, coil mandrels, sheet bundles, or injection molds need to be rotated. The manual control pendant ensures the entire process is fully controlled and safe.

As a manufacturer, we supply upenders in a variety of configurations tailored to customer requirements. A wide range of loading platform designs (smooth, prism-shaped, with clamps, or rounded) ensures safe rotation of components with diverse geometries.

Key Benefits of WO Upenders:

Ensures operator safety

Prevents damage to the rotated workpiece

Prevents floor damage

Minimizes rotation time

High-quality chains combined with a self-locking gearmotor (up to 10 tons) or an automatic pneumatic disc brake system (above 15 tons) ensure maximum safety and long-term reliability.

The ideal solution for the safe rotation of steel coils and injection molds

| Model | Weight of rotated part (kg) |

Tipping time (s) |

Loading plate dimensions (mm) |

Voltage (V) |

|---|---|---|---|---|

| WO-3T | 3000 | 25 | 1100x1100 | 3x400 |

|

||||

| WO-5T | 5000 | 30 | 1100x1100 | 3x400 |

|

||||

| WO-10T | 10000 | 40 | 1500x1500 | 3x400 |

|

||||

| WO-15T | 15000 | 40 | 1700x1500 | 3x400 |

|

||||

| WO-20T | 20000 | 40 | 1900x1500 | 3x400 |

|

||||

| WO-30T | 30000 | 40 | 2000x1800 | 3x400 |

|

||||

ACCESSORIES AND OPTIONAL FEATURES:

– Polyurethane-coated loading plates

– Safety fences / enclosures

– Safety barriers

– Operator platforms

– Programmable control systems

The upenders are equipped with a smooth braking system. As the platform approaches its end positions, it decelerates gently and comes to a controlled stop.

All upenders are equipped with motors featuring integrated brakes, allowing the rotation to be stopped at any moment without the risk of unintended movement of the workpiece.

Solutions tailored to your needs

Our Design Department combines years of expertise with innovative thinking to deliver fully customized solutions. We design machines that go beyond standard models, precisely tailored to your specific requirements.

Flexible solutions

Flexible solutions Individual approach

Individual approach Focus on safety

Focus on safety Easy expansion

Easy expansion